Description

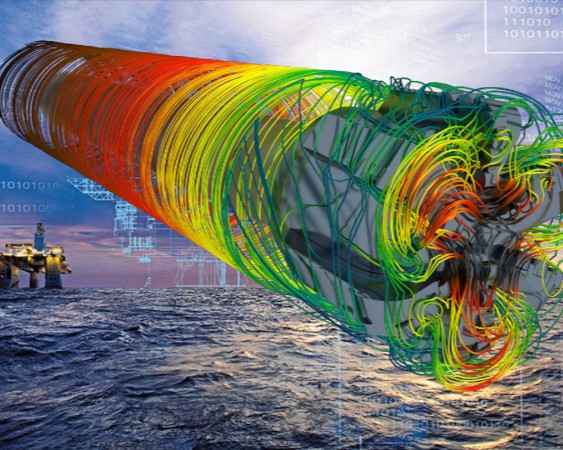

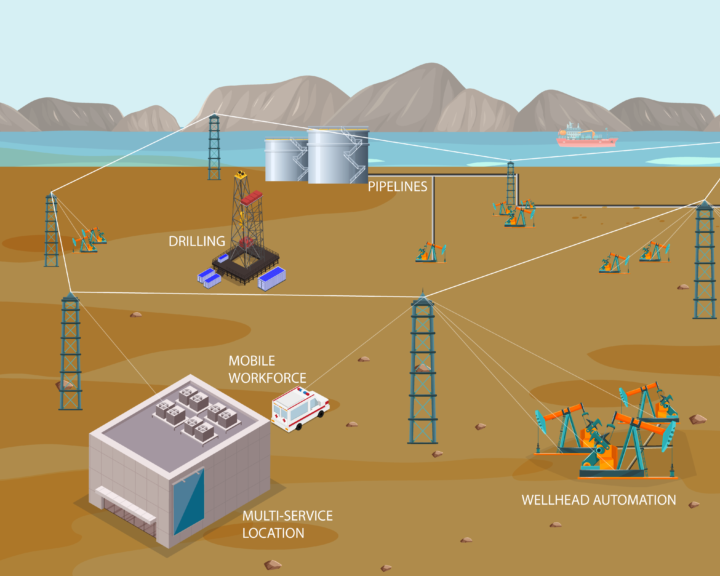

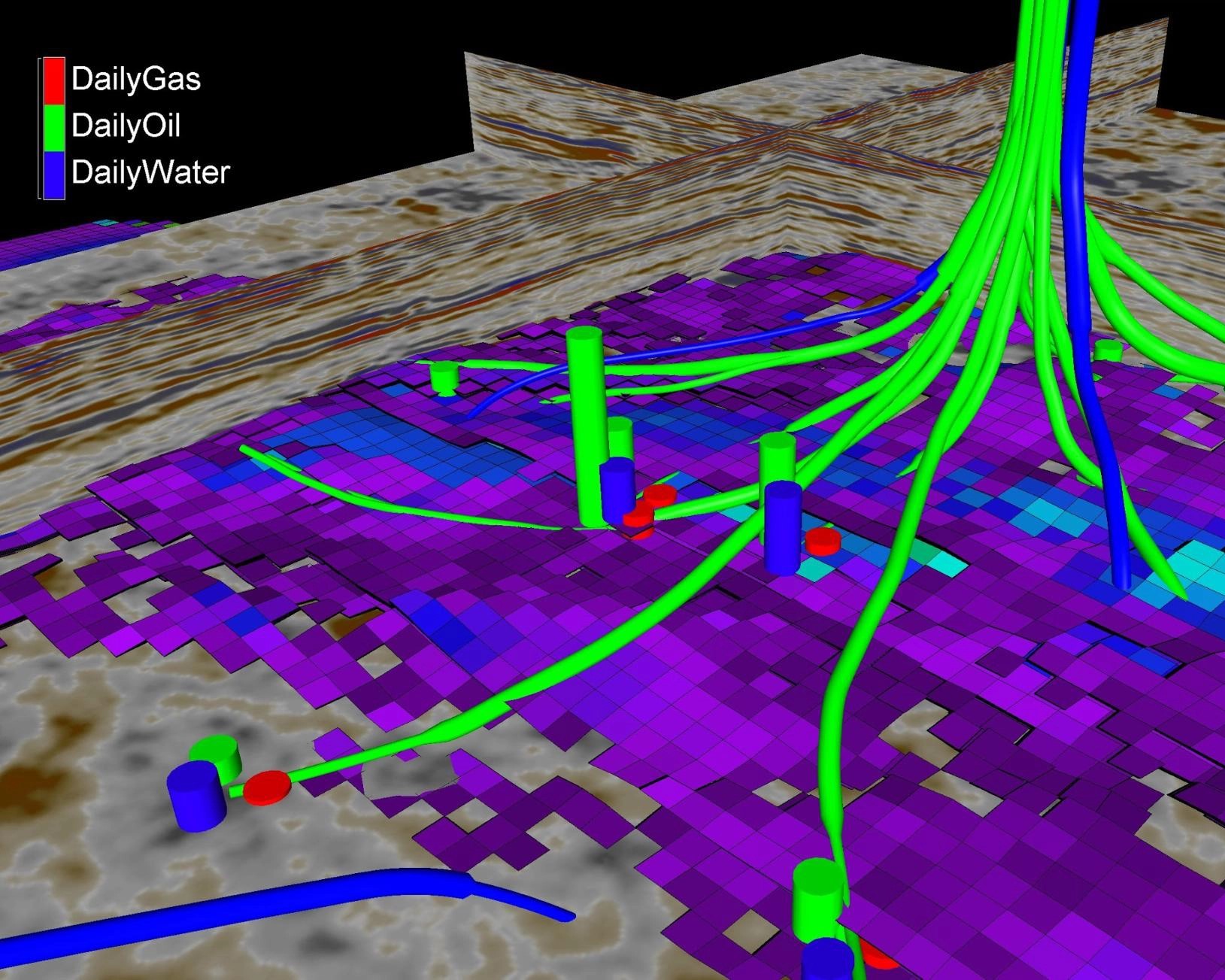

Process simulation software for oil, gas, and chemical facilities is a comprehensive solution designed to replicate, analyze, and optimize industrial processes in a virtual environment before implementation in the real world. The platform allows engineers and operators to create highly detailed models of process units such as distillation columns, heat exchangers, reactors, separators, and pipelines, simulating the behavior of fluids, gases, and chemical reactions under a variety of operating conditions. By using advanced thermodynamic models and dynamic simulation capabilities, the software can predict process performance, energy consumption, pressure and temperature profiles, and product quality. This enables process engineers to identify inefficiencies, test process modifications, and evaluate the impact of operational changes without risking plant downtime or safety incidents. It supports design validation, troubleshooting, process optimization, and safety analysis by allowing virtual experimentation with different operating scenarios. Integration with plant data and instrumentation systems enhances model accuracy, while the software’s analytical tools can perform sensitivity analysis, optimization studies, and predictive maintenance planning. Safety-critical evaluations, such as identifying potential bottlenecks, runaway reactions, or process deviations, can be simulated, helping operators develop contingency strategies and comply with regulatory standards. The platform also enables economic evaluation by estimating production costs, energy usage, and environmental impacts. Collaborative features allow multidisciplinary teams, including process engineers, operators, and management, to work together seamlessly. By leveraging process simulation, facilities can achieve higher efficiency, reduce energy consumption, minimize waste, and improve overall production reliability. The solution is applicable to a wide range of facilities, including oil refineries, gas processing plants, petrochemical complexes, and chemical manufacturing sites. Ultimately, process simulation provides a risk-free environment to optimize operations, ensure safety, and maximize profitability, bridging the gap between engineering design and practical execution.

Chuks –

“Process simulation has been a game-changer for optimizing our gas processing plant. We previously struggled with bottlenecks in our dehydration unit. The simulation pinpointed the exact cause, and after implementing its recommendations, we saw a 15% increase in throughput. Excellent software backed by responsive, insightful support.”

Alex –

“Implementing ‘Process Simulation’ revolutionized our debottlenecking studies. Its accurate modeling identified a subtle pressure drop issue we’d missed, averting a costly shutdown. The team’s prompt support and clear communication ensured seamless integration, improving our throughput by 7%.”

Ishaq –

“Process simulation transformed our bottleneck-prone gas processing unit. The team pinpointed hidden inefficiencies within days. We’ve seen a 12% throughput increase and a significant reduction in flaring thanks to their robust simulations and readily available expert support. Quality execution from start to finish.”

Hamsatu –

“Before, optimizing our LNG plant felt like educated guesswork. ‘Process’ provided clarity. Its simulations pinpointed bottlenecks we’d missed, boosting production by 7% within a month. The team’s rapid response to our complex queries and their commitment to quality made this an invaluable tool.”

Wilson –

“Before, optimizing our ethane recovery felt like guesswork. ‘Process simulation’ allowed us to pinpoint inefficiencies in our cryogenic unit. The team’s responsive support and the software’s accurate modeling have directly increased our NGL production, boosting profitability while minimizing downtime.”